Robotics

3D printing robots, AI in manufacturing, AI-powered robots in industry, automation in manufacturing, autonomous robots in industry, collaborative robots, factory automation, future of industrial robots, industrial automation, industrial robotics, industrial robots for assembly, manufacturing robots, robot technology in industry, robotic arms in industry, robotics and efficiency, robotics and precision, robotics in construction., robotics in production, robotics in quality control, robots and productivity, robots and workforce, robots in agriculture, robots in automotive industry, robots in factories, robots in heavy industries, robots in industry, robots in logistics, robots in packaging, robots in supply chain, robots in warehousing, smart manufacturing

fxmwj

0 Comments

How Are Robots Changing Industry?

The rise of robotics is transforming industries worldwide. From manufacturing to healthcare, logistics, and beyond, robots are reshaping how businesses operate, improve efficiency, and increase productivity. In this article, we’ll explore the significant ways robots are changing industries and revolutionizing how work is done.

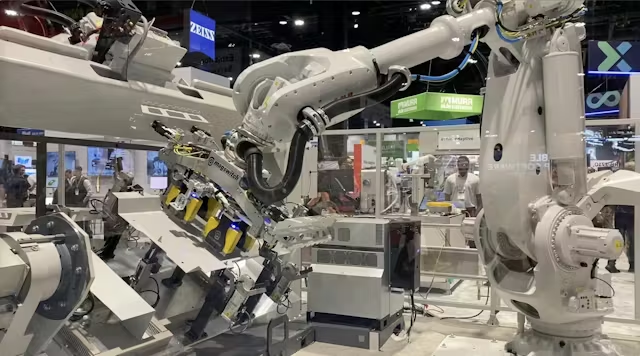

1. Revolutionizing Manufacturing

Robotics has long been a cornerstone of the manufacturing industry, but with the advent of advanced robotics, it’s taking on a much more sophisticated role.

- Automation and Efficiency: Robots in manufacturing plants have taken over repetitive and physically demanding tasks, improving production speed and consistency. Tasks such as assembly, welding, painting, and packaging are now largely automated, allowing human workers to focus on more complex, decision-based roles.

- Precision and Quality Control: Robots equipped with sensors and AI can perform tasks with high precision, reducing defects and enhancing the overall quality of products. This capability is especially valuable in industries like automotive and electronics, where product quality is critical.

- Collaborative Robots (Cobots): Cobots work alongside humans in a shared workspace. These robots are designed to be safer and more flexible, performing tasks that complement human workers. For example, a cobot might assist with heavy lifting, while the human worker performs quality control or troubleshooting tasks.

2. Revolutionizing Logistics and Warehousing

In the logistics and warehousing industries, robots are drastically improving efficiency and transforming operations:

- Autonomous Vehicles and Drones: Robots like autonomous forklifts, delivery robots, and drones are now commonplace in warehouses and distribution centers. These robots can transport goods, sort packages, and even perform last-mile deliveries without human intervention.

- Inventory Management: Robots equipped with AI can monitor stock levels, track inventory, and even restock shelves in real-time. This capability ensures that businesses can maintain accurate inventory levels and reduce the chances of overstocking or stockouts.

- Reduced Labor Costs: The automation of warehouse tasks is reducing the need for manual labor and improving cost-effectiveness. While some jobs are displaced, robots also create new roles in managing and maintaining automated systems.

3. Enhancing Healthcare Services

Robots are making a significant impact on the healthcare industry, with applications ranging from surgery to patient care.

- Robotic Surgery: Advanced robotic systems are enabling surgeons to perform minimally invasive procedures with greater precision. For example, the da Vinci Surgical System allows surgeons to operate with enhanced control and flexibility, leading to shorter recovery times and fewer complications.

- Elderly and Disabled Care: Robots are being designed to assist elderly individuals or people with disabilities. These robots can help with everyday tasks like feeding, dressing, or moving, improving the quality of life for individuals who need assistance and allowing caregivers to focus on more complex care needs.

- Robotics in Rehabilitation: Robots are also helping patients recover from injuries. Robotic exoskeletons and physical therapy robots assist patients in regaining movement, strength, and mobility after injuries or surgeries.

4. Transforming Agriculture

The agriculture industry is also benefiting from the integration of robotics and automation.

- Precision Farming: Robots equipped with AI and sensors can monitor soil conditions, track crop health, and even plant seeds. This level of precision ensures that crops receive the right amount of water, fertilizer, and treatment, which reduces waste and increases yield.

- Automated Harvesting: Robots are now capable of harvesting crops like fruits and vegetables, helping to address labor shortages in agriculture. These robots are designed to work around the clock, improving harvest efficiency and ensuring that produce is picked at the right time.

- Pest Control: Autonomous drones and robots can monitor crops for pests and diseases, ensuring timely intervention without the need for harmful pesticides. This reduces the environmental impact of farming and promotes sustainable practices.

5. Improving Retail and Customer Service

In the retail industry, robots are enhancing customer service and transforming the shopping experience.

- Robots in Retail Stores: Robots are increasingly being used for inventory management, restocking shelves, and even assisting customers with product recommendations. In some stores, robots help guide customers to products or provide them with personalized shopping experiences based on their preferences.

- Automated Checkout: Self-checkout kiosks and automated payment systems are improving the efficiency of the retail experience. Robots can scan items, process payments, and provide receipts without the need for human cashiers, speeding up the checkout process.

- Delivery Robots: In urban areas, robots are being deployed for last-mile delivery, ensuring faster and more efficient delivery of goods. These robots are designed to navigate streets and deliver items directly to customers, reducing delivery costs and time.

6. Advancing Construction

The construction industry is also witnessing a revolution thanks to robotics.

- Automated Building: Robots are now being used in construction to automate tasks such as bricklaying, welding, and even 3D printing buildings. This reduces the time it takes to build structures and increases the precision of the work being done.

- Robotics in Hazardous Environments: Robots can be deployed in dangerous or hazardous environments, such as working on high-rise buildings or in contaminated areas. This allows construction companies to reduce worker risks while maintaining productivity.

- Drones for Site Inspection: Drones are used for surveying construction sites, monitoring progress, and inspecting structures for defects. These drones provide real-time data and aerial views, making it easier for construction managers to monitor large-scale projects.

7. Impact on Jobs and the Workforce

While robots are increasing efficiency and productivity in many industries, they are also raising questions about the future of work. As automation takes over routine, repetitive tasks, there is concern about job displacement. However, robots also create new jobs in fields like robotics engineering, AI development, and robot maintenance. Workers in traditional industries may need to reskill and adapt to new roles that involve managing or collaborating with robots.

Ultimately, the challenge will be ensuring that the workforce is prepared for this shift. By investing in education and training programs, industries can help workers transition into new roles that leverage the potential of robotics and automation.

Also Read : What Is the Future of Robotics?

Conclusion

Robots are changing industries in profound ways, improving efficiency, reducing costs, and enabling new capabilities that were once thought impossible. From manufacturing and logistics to healthcare and agriculture, robots are transforming the way businesses operate and interact with customers. While this transformation brings challenges—especially concerning labor and job displacement—it also presents new opportunities for growth and innovation. As robotics technology continues to advance, we can expect even more industries to embrace automation, leading to a future where humans and robots work together to drive productivity and progress.

Post Comment